Providing the best results for clients: that’s what most contractors strive for. And Kruse Smith is no different. That’s why the Norwegian contractor has recently started digitalizing their work for the E39 highway project. As part of this process, they took a special focus on technological innovations and how those could improve their on-site performance. That has allowed them to minimize any repetition, time consumption, and labor costs associated with their work while producing more cost-effective and timely end results.

More specifically, it has allowed them to effectively develop the 19 km (11.8 mi) of the E39 project that they are responsible for.

However, the project as a whole is likely to be the largest coastal highway infrastructure Norway has ever conducted. At about 1,100 km (683.51 mi), the project is expected to replace multiple ferry travel points and cut down travel time from 21 hours to just 13.

To optimize their part in this extensive project, Kruse Smith conducted a digital pilot project, enacting innovative changes, such as replacing paper plans with 3D modeling and BIM and using wireless sensors for concrete monitoring.

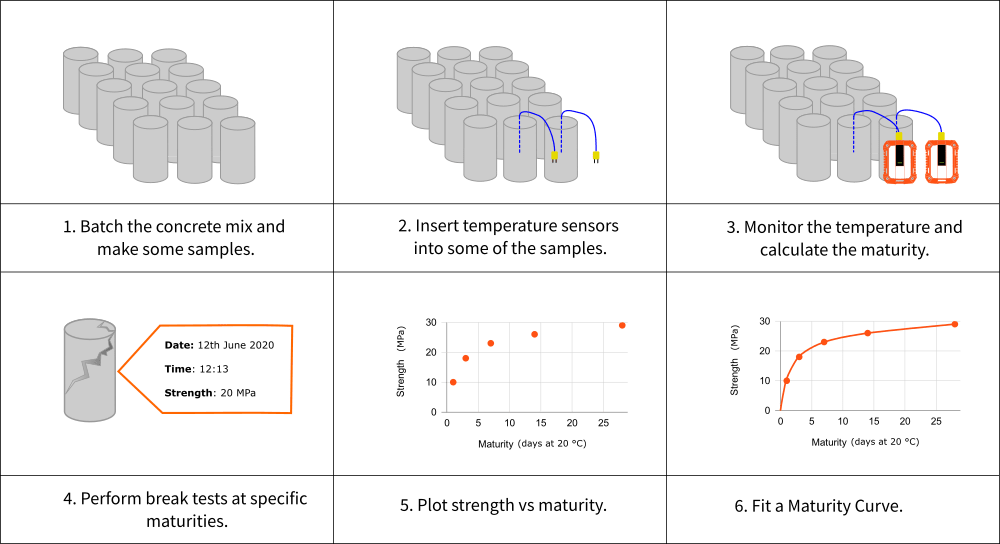

These wireless sensors (also known as Maturix Smart Concrete Sensors) help optimize Kruse Smith’s work on-site by enabling the contractor to remotely monitor the temperature and strength development of multiple concrete structures in real time. It’s a method that saves them time and money that they would have otherwise spent on physically checking each concrete form.

For more details on how this innovative technology is helping the contractor move forward on the E39 project, the creator of Maturix, Sensohive Technologies ApS, conducted an interview with two members of Kruse Smith’s team, Marius Røksland, and Asbjørn Stålesen.

The interview gave great insight into the use of Maturix in the infrastructure project. And we are happy to add to the conversation, sharing additional interview details on how Maturix helped Kruse Smith in their everyday work.

To talk about Kruse Smith’s work on the E39 project and their use of Maturix, we have two members from their team. Can you tell us a little bit about yourselves?

Marius: My name is Marius Røksland, and I work for Kruse Smith as a project engineer.

Asbjørn: I am Asbjørn Stålesen, and I’m the project manager for the new E39 between Kristiansand and Mandal.

What are you currently working on?

Marius: At the moment, at this jobsite, we are building 19 bridges, completing the new E39 highway. It’s a four-speed, 110-kilometer [68-mile] highway on the coast of Norway, all the way south. It is one of many small stretches of roads that we have been constructing.

For this one, now, we have been working for a couple of years and still have one-and-a-half years to go.

This bridge is about 370 meters long. It’s a dual lane, so we are doing two at the same time.

How far are you with the bridge?

Asbjørn: Currently, we are 90-, 95-percent finished. We have cast all three bridges, but we have some of the small works around them left before we can hand them over to the client.

On this particular project, we have all cast-in-place. We have no precast, and we do this with quite big formworks.

These are 120-meter [393.71-foot] bridges, but we reuse the formworks from one to the other. So we try to do as much of that as we can, but it’s important for us to think industrial scale because we’ve been building so many bridges in such a short time. This is also why monitoring the curing process enables us to move on a lot faster as we know exactly when we can remove the formwork.

What are the challenges of this project?

Marius: The weather is a challenge as it is way too cold. We have problems with ice and snow here in Norway, especially now when it’s so cold. So it’s important for us to know the concrete temperature in the whole bridge and every cast. This has mostly to do with the maximum temperature, but also now in these conditions, we really have to be careful not to have anything freeze until we get the curing.

There are also different aspects, but mostly, that the temperature may not differ too much from the core to the outer edges as the structure can get damaged otherwise. In the current temperatures with the cold, it is a challenge. So we really need to monitor the temperature!

Did you always monitor the concrete temperature in mass concreting?

Asbjørn: It’s always been a requirement that we monitor, but the other systems we used were offline. That means that you go and collect the data and you come back and analyze it.

This also means that in real life, you do this more than one time — maybe once if you’re lucky — and directly get the required result.

Marius: Before Maturix, we used manual data loggers. They were digital, but not wireless. Then, you had to take the sensors, set them up, leave the sensors, cross your fingers, and hope for the best. And then, some days later or some hours later, you have to go back out to the form, check whatever reading there is, collect it, put it into the computer, and see what you actually get.

Asbjørn: So even with the data loggers, it is still very time-consuming to set them up and go get them. Also, you really don’t know what the data looks like until you actually finish the casts and do the analysis. (With Maturix, you get all the graphics and analysis on the screen — live.) And you don’t get any chance of doing something as you progress through the curing process.

That means that you’re not really actively using the data. You’re crossing your fingers and hoping that everything has gone well, and afterwards, you have documentation that it did. It’s a very passive way of working compared to having the data available at all times.

How do you actively use the data?

Asbjørn: So that’s one aspect of it — better active documentation and quality control. Another is, if we forgot something and suddenly there is a change like a temperature drop or some kind of temperature change or another concrete mixture — or if it gets too hot, for instance — or you were expecting to see this curing process start in, say, eight hours, but you didn’t get it until it was 14 hours? Then, we can investigate further why and potentially save time next time by adjusting the mixture or doing some additional work prior to casting.

So, are you using the monitoring data to optimize future casts? Has that influenced internal teamwork?

Asbjørn: Yes. We see that in everyday life, we’re using the data so much more, and discussions around it have been brought up. The temperature data becomes an everyday topic instead of being something that a quality engineer does and documents. And we see that the data has been actively used to improve how we build.

How important is the monitoring data for you, and how do you use it?

Asbjørn: It’s important for us at all levels. For me, as a project manager, it’s important to keep control of all the work going on. We have work in a lot of different sites, and this enables me to keep track of ongoing castings and how they are doing. So basically, we can monitor the situation in real time so that we know what’s going on.

But it’s also important for us in everyday work, where we have control over all the curing processes at a much better level now. And we can much more accurately predict when the concrete is cured and when we can go to the next step.

But it’s also good from a quality aspect. We can use it in meetings and discuss how the castings are going and which areas of concern there might be or how we can adjust for future casts.

Marius: We can check whatever the concrete is doing and share the information with the client. That creates a lot of transparency and trust.

Who has access to the monitoring data?

Asbjørn: Well, we have chosen to share the access to the software with both our clients and third-party members. So everybody has full access to all the data, and the feedback from that is very good! They check the data, and they discuss it with us. We have a very good dialogue with all parties, and we get to share the knowledge of how to improve our quality of work.

It gives a whole new level of trust, showing them that we have nothing to hide. And this is very good to have in a project like this!

So, how easy do you think it would be for someone who has not used Maturix before to get started?

Asbjørn: We’re finding now that it doesn’t take much training at all and that people are really on board. People are really interested and want to use it as much as possible here, and it’s certainly not a system we will go away from. It has come to stay with us.

Marius: You just take the cable, connect it to the transmitter, start it in the software, and you are ready to go. It’s super easy to get started.

What would you tell someone who is considering Maturix?

Marius: I think it would be better to show them. You get everything that you need, plus a lot more! You get all the data and don’t need to be on-site or do the analysis, so it just is better and quick and easy.

Asbjørn: I’m firmly recommending using the system. It gives you much more insight into what you’re doing. Also, together with your client, it gives you better client relations and a higher quality of work. So in my mind, this is the way forward!

Thank you so much for taking the time to talk with us, and good luck with your work on the E39 project!

The post Interview: Why Maturix® Is Contractor Kruse Smith’s Chosen Concrete Sensor appeared first on Kryton.