Sustainable architecture and concrete are not always considered compatible. After all, the production of concrete is known as the cause for at least 8% of the world’s carbon emissions. It’s why many concrete producers nowadays are creating their own low-carbon concrete mixes. And it’s also why some architects are hesitant about their use of concrete.

That is especially the case now as the effects of climate change advance. With this progression, people are seeing an increase in severe storms and heat waves. They’re also seeing a significant rise in temperature in the Arctic. It’s warming up two-and-a-half times faster than any other region on the planet. To better visualize this, consider that the New York Times has noted the average air temperatures in 2019 for the world were around 3.5°F (1.9°C) higher than the average temperatures found from 1981–2010. Because of this, the Arctic’s ice is melting away, leaving behind more ocean to absorb sunlight and radiate more heat. All of which heats up the rest of the planet that much more.

In response to this, many architects have felt a stronger need to incorporate sustainability into their work. For instance, a number of architects have chosen to solely work with clients who are aiming to build to net-zero energy standards. Though, not all such sustainability efforts have been this recent in the world of architects. The American Institute of Architects itself has had a commitment to sustainability for as long as 1971. And architects have only been increasing their focus on this commitment to sustainable architecture ever since.

With their concerns over the state of the climate, architects have become a little wary about using concrete. However, concrete remains an incredibly common building material. And there’s good reason for that. Whatever you think of it personally, concrete has much to offer sustainable architecture!

For One, Concrete Can Create One of the Most Energy-Efficient Walls Available

Known as insulated concrete form (ICF) walls, these structures are considered to be one of the most energy-efficient forms available. In fact, according to Concrete Construction, back in 2009, ICF walls were what gave Beverly Stevenart, the co-owner of Craftsman Homes & Design, in Colorado from the United States of America (USA), a way to construct a net-zero energy home. They’re also a form that the New York City-based Curtis + Ginsberg Architects have frequently used over the years to great effect in a number of projects. These include the Calvert Lancaster building on Lexington Avenue, which earned a silver certification in the Leadership in Energy and Environmental Design (LEED) program. They’ve also achieved multiple other LEED and passive house certifications with their ICF construction.

ICFs have not just been benefitting sustainable architecture in the USA, though. While places outside North America focus a little less on ICF construction, it still plays a big part in Europe and is gaining traction in regions like Asia, South America, and the Middle East.

But how does it work?

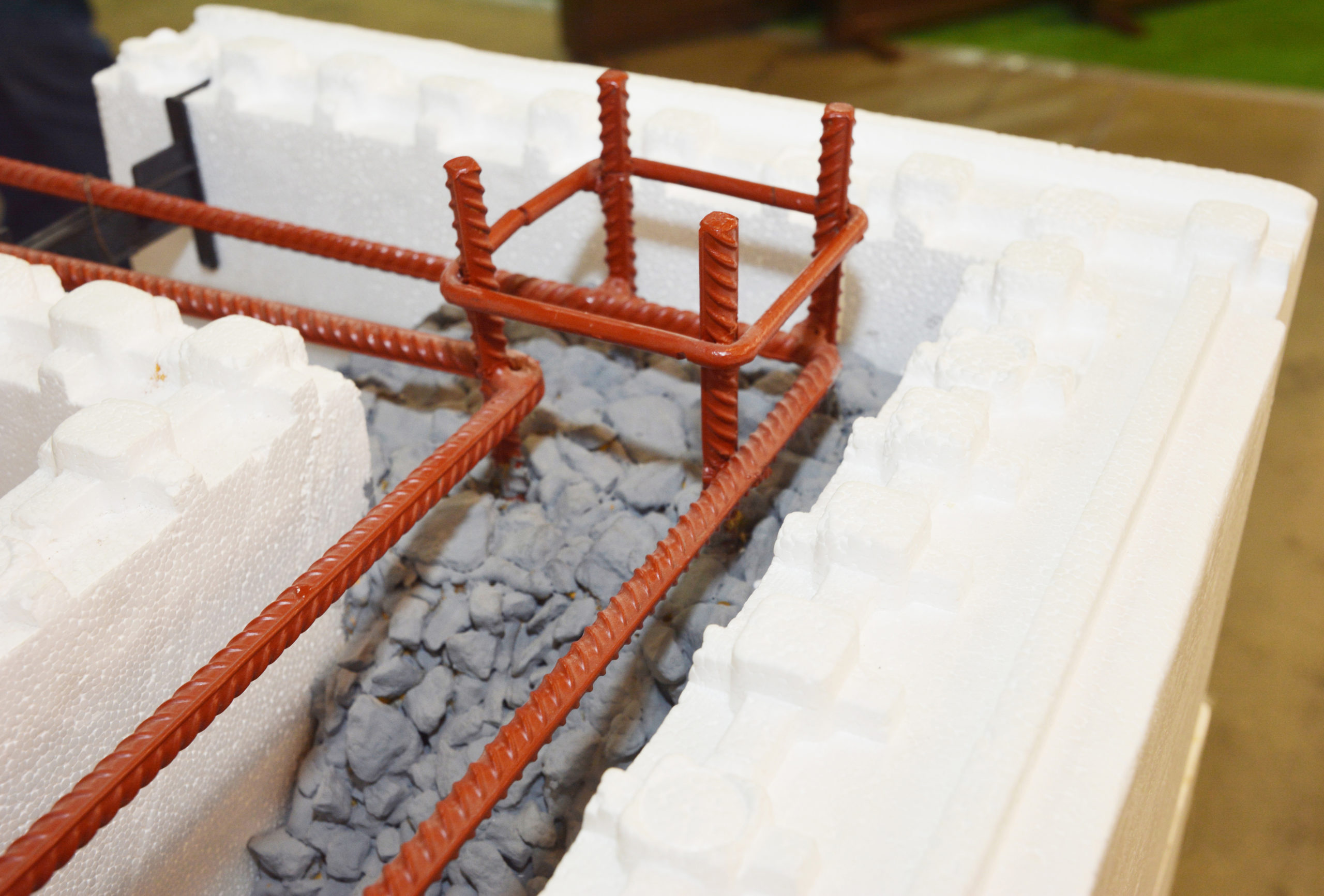

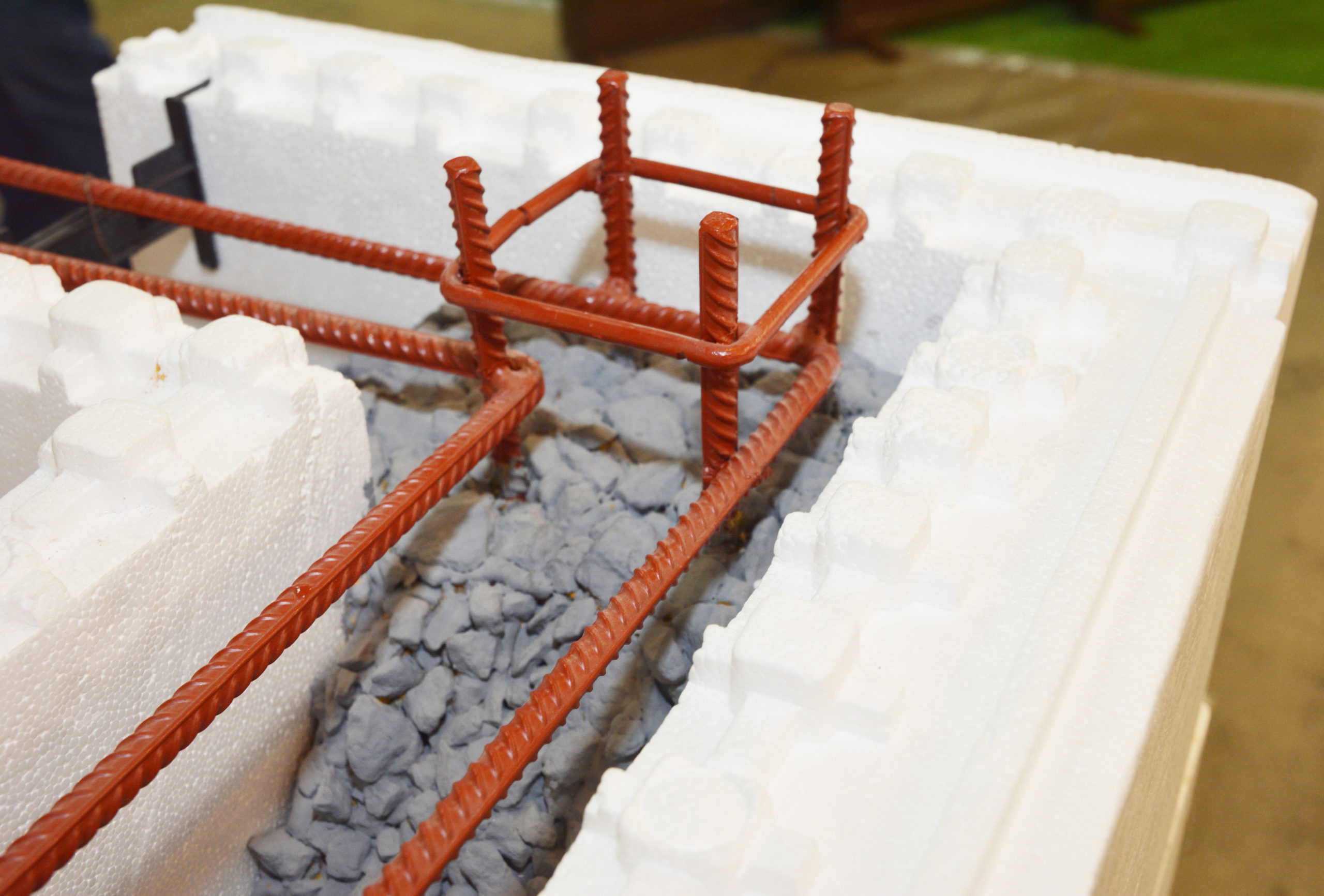

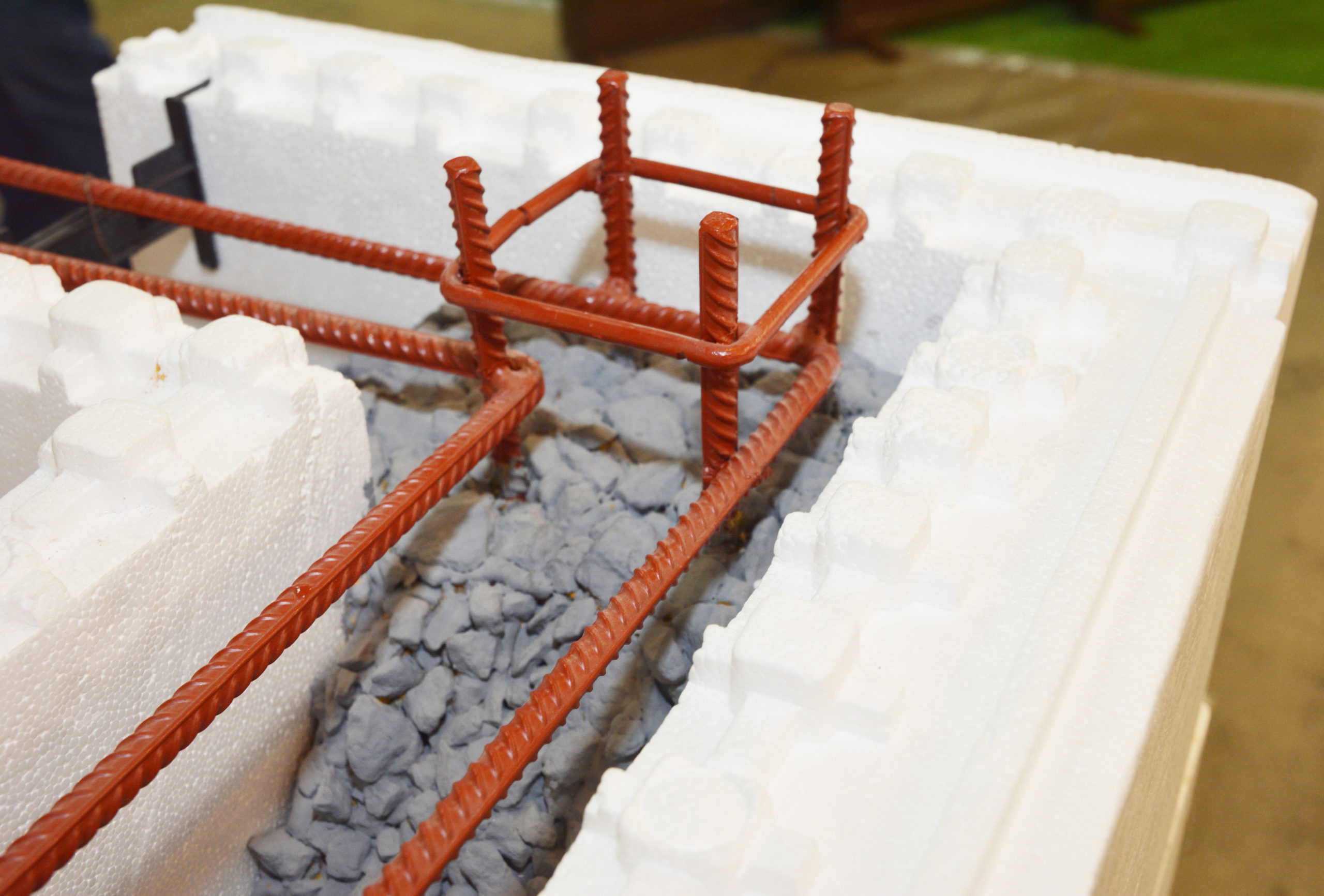

Well, let’s look at how ICFs are made first. At the start, they’re molded from either expanded or extruded polystyrene. This mold then typically takes on the form of lightweight open-cell concrete blocks or panels. These then act as the forms for poured concrete (which can be for above or below grade walls). The end result is a number of walls that combine the benefits of concrete and integral insulation. From concrete, the walls gain a decent amount of thermal mass and strength. And from the integral insulation, the walls receive a number of energy-saving benefits. All of which makes them highly energy efficient and even more thermally efficient than traditional wood-framed assemblies.

These Happen to Manage Temperature Well and in Different Climates

That is great news for architects looking to cut down on energy loss for their sustainable architecture. With the thermal efficiency of ICF exterior walls, they can create a design that uses less energy to cool down and warm up compared to wood-framed houses. Based on estimates from the home performance magazine Home Energy, that equates to ICF exterior walls cooling down with around 32% less energy and warming up with 44% less energy than a wood-framed house would. The estimated savings for this amounted to an average of $200 a year.

Of course, the average energy saved in all this does depend a bit on the surrounding climate. For colder areas in North America, the buildings might save more on heating than cooling. The reverse can be said for warmer areas.

Still, no matter the climate, the ICF walls will still provide energy savings. To confirm this and compare the performance to code-matching and wood-framed homes, the Portland Cement Association (PCA) conducted a study. For this study, they looked at the performance of homes in several cities across the USA. These were Chicago, Miami, Phoenix, Seattle, and Washington D.C. After observing each location, the PCA noted that the homes with ICF walls saved significantly on energy. Compared to code-matching homes, the ICF-constructed ones used 8% to 19% less energy. And compared to wood-framed homes, they used 5% to 9% less energy. On top of that, they even exceeded the requirements from the International Energy Conservation Code.

What’s more, ICF walls can also absorb the temperature swings of any climate. This is mainly thanks to their concrete thermal mass, which allows them to absorb heat. In turn, this heat can help them regulate the internal temperature of a building. So, for instance, if the building is in a desert, its ICF walls will absorb the day’s heat. Then, by the time it becomes freezing at night, the heat from the concrete will still keep the interior’s temperature relatively warm and stable.

nd They Provide a Tight Design That Allows for More Cost-Effective HVAC Systems

ICF walls aren’t just great for dealing with energy loss and temperatures. They also provide a tighter fitting design, which works well for energy efficiency in other areas. One area in particular is structural leaks. With the tight design of ICF walls, there’s less room for air leakages and outside air infiltration. Confirming this fact, one PCA study noted that ICF walls had an air leakage rate of 0.15 air changes per hour, while wood-framed homes had 0.78 air changes per hour.

To add to that, the design of ICF walls allow for smaller and more affordable HVAC systems. Because ICF construction doesn’t need as much HVAC energy, construction teams can choose a more compact and affordable setup. That also allows them to save around $500–$2,000 per home while still supporting sustainable architecture.

Those Aren’t the Only Benefits They Provide Either

They also come with the following advantages for sustainable architecture over other walls like wood-framed ones:

Better fire resistance — According to research done by the U.S. Department of Housing and Urban Development, ICF walls offer some of the best fire resistance available. For instance, they can endure fires at extreme levels for up to four hours, while wood-framed walls generally do not last more than a one-hour fire rating. This is because concrete is not an organic material that would fuel a fire. So unlike wood, which can contribute to fire growth, concrete can avoid exacerbating it while resisting damage at the same time.

Increased durability — Known to be a long-lasting material, concrete has gotten this reputation due to its ability to resist wear and tear, severe weather, rot, insects, and fire. And the ICF walls that concrete can create can do the same while also resisting moisture. Likewise, wood-framed walls can have a similar form of resistance from environmental factors when placed in the interior of a building. However, as the U.S. Department of Housing and Urban Development notes, they are still vulnerable to rotting if water manages to get into the building. They’re also vulnerable to termite attacks, which can cause a fair bit of structural damage.

Stronger noise control — The publication Construction Canada suggests that ICF walls may even provide up to 40% lower sound transmission compared to wood-framed walls. Backing up that idea, the U.S. Department of Housing and Urban Development’s study states that a typical wood wall may have a sound transmission class (STC) rating of 35 to 49, while ICF walls will have a rating of 48 to 58. So the sound of shouting could likely be heard through the wood-framed walls, but less so for ICF walls. Of course, there is also the option of using enhanced wood walls as well, which doesn’t quite reach the STC ratings of ICF walls. But it gets pretty close, hitting the 50 to 54 STC rating. Still, for the best noise control, ICF walls offer the better bet.

Fewer potential insurance concerns — Depending on the region, building owners may also deal with fewer insurance concerns if their structure uses concrete materials. In Vancouver, Canada, for example, GLOBE Advisors underwent research to compare the insurance costs between mid-rise wood-framed buildings and concrete residential buildings. The end results of that research showed that while there is a risk of water damage to concrete buildings, generally that damage is easier to find and resolve compared to the damage found in mid-rise wood-framed buildings. With wood construction, moisture concerns are harder to detect so they can fester for years, and if they’re not found in time, they can render a building uninhabitable. Additionally, wood-framed buildings come with a higher risk of fire and mold compared to concrete buildings. All of which can lead to higher insurance rates as insurance companies want to deal with as little risk as possible.

Of Course, Concrete on Its Own Has a Number of Sustainable Traits

Concrete isn’t just a way for architects to build energy-efficient ICF walls with benefits. It’s also a material that comes with its own sustainable traits.

For One, It’s Quite Versatile, Allowing It to Fulfill a Variety of Design Needs

With this versatile nature, concrete makes a project design that much easier to complete. It allows builders to choose what type of consistency it’ll have, how it’ll flow, what setting times it’ll have, and which hardened properties it’ll use.

They can even affect each of these aspects while adding beneficial qualities through the use of admixtures. So if they want to avoid petroleum-based waterproofing membranes, they can directly add an admixture like the Krystol Internal Membrane

(KIM to a concrete mix. That allows them to make the concrete inherently and permanently waterproof without the need for toxic elements or volatile organic compounds (VOCs). KIM will also protect the reinforcement from corrosion, which can extend the structure’s life cycle and reduce future maintenance expenses.

The same goes for when they want to enhance the concrete’s durability against abrasion. They can replace dry shake hardeners and sealers, which can expose workers to silica dust and VOCs, with the durability admixture Hard-Cem. Adding it directly to a concrete mix gives the concrete a high resistance to both abrasion and erosion, doubling its life span.

All of which makes it possible to use concrete in a wide variety of applications while ensuring the structures they form remain functional now and in the future. After all, concrete represents an investment, and it is critical to ensure that investment will last. Admixtures make this possible while adding more benefits and reducing the amount of carbon pollutants that are emitted throughout the building’s life cycle.

On Top of That, Concrete Is Reusable

Even if a concrete project is eventually set for demolition, it is still possible to reuse it! That remains the case even if the concrete has rebar within it. That’s because workers can separate the rebar from the concrete with large magnets to be reused for future projects. And they can then crush the concrete into fragments of varying sizes. These fragments can then help create the following:

Pavement for walkways and drivewaysBed foundation material for trenchesLandscaping mulchFill for wire cagesOceanic reef habitats

Most significantly, though, they can act as replacement for aggregate in concrete mixes. That helps builders reduce the amount of gravel and sand extraction needed. And that in turn is better for sustainability as it lowers the amount of resource extraction that occurs in construction.

Of course, it’s important to note that this sort of reusability only works for concrete with no contaminating substances. After all, concrete with calcium sulfate, chlorides, oils, or surface-applied membranes can render the concrete unsuitable for reuse, meaning it ends up in a landfill.

But concrete without those concerns, from start to finish, can be a great ally to sustainable architecture. While it can also be a carbon-intensive material, the construction industry has been hard at work producing better alternatives. From that mindset, we’ve come up with energy-efficient ICF walls, admixtures that reduce carbon emissions, and ways to reuse concrete. So for worried architects, using concrete does not have to be a cause for concern. In fact, it could aid you in your design for a greener, more sustainable building.

The post Sustainable Architecture and Concrete: Why They Can Work Well Together appeared first on Kryton.